The Last Planner System (LPS) is a widely recognized methodology for improving production reliability in construction. However, its origins and development are often misunderstood. This article traces the LPS’s history, from its roots in 1980s research to its current status as a globally implemented system. Understanding this evolution is crucial for anyone seeking to effectively leverage the LPS in their projects.

The Precursors: Early Experiments in Production Control

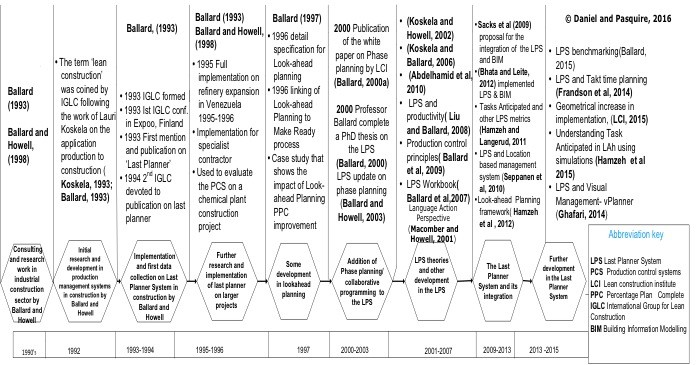

The foundation for the LPS wasn’t born from a sudden breakthrough, but rather from incremental improvements in construction project management. As early as the 1980s, Glenn Ballard, then Productivity Improvement Manager for Brown & Root Construction, was already experimenting with principles that would later define the LPS. These included the concept of “making work ready” – ensuring tasks were fully prepared before assignment – and proactively shielding workers from poorly defined or unrealistic assignments.

These early practices weren’t yet formalized as a system, but they laid the groundwork for a more structured approach to production control. It would take another decade of refinement before the “Last Planner System” emerged as a cohesive methodology.

The Formalization of the LPS: The 1990s Breakthrough

The LPS as we know it today took shape in the early 1990s, largely through the consulting work of Glenn Ballard and Gregory Howell in the industrial construction sector. Their practical experience highlighted the need for a system that could improve workflow and enhance the predictability of project outcomes.

Crucially, the LPS wasn’t derived from the Toyota Production System (TPS) – a common misconception. Instead, it was specifically developed by construction professionals for the construction industry, addressing its unique challenges. The initial focus was on improving workflow and increasing plan reliability – principles that remain central to the LPS today.

The Birth of Lean Construction: A Pivotal Collaboration

The LPS’s development was deeply intertwined with the emergence of “Lean Construction” as a field of study. In 1992, Lauri Koskela’s seminal work on applying production principles to construction provided a theoretical framework that perfectly complemented the LPS’s practical approach.

This collaboration led to the formation of the International Group Lean Construction in 1993, with its inaugural conference held in Espoo, Finland. It was at this conference that the term “Last Planner” was first introduced and published in the proceedings. Early implementations of the LPS on construction projects followed soon after, culminating in a full-scale implementation on a major refinery project in Venezuela between 1995 and 1996.

The Evolution of Principles and Research

Over time, the LPS has evolved beyond its initial core principles. While improving workflow and plan reliability remain central, the system has been supplemented by ongoing research and development. A key milestone was the discovery in 1996 of the link between Look-ahead Planning, the “make ready” process, and the resulting improvement in the Percentage Plan Complete (PPC) – a crucial metric for measuring project performance.

Glenn Ballard’s 2000 PhD thesis, “Last Planner System of Production Control,” remains the most influential publication on the LPS, with over 832 citations as of recent Google Scholar searches. This work has formed the foundation of Lean Construction education at universities worldwide.

Integration with Other Methodologies

The LPS hasn’t remained isolated. It has been successfully integrated with other methodologies, including Building Information Modeling (BIM), Location-Based Management Systems, Takt Time planning, and visual management techniques. Numerous commercial software products have also been developed to support LPS implementation.

Current Trends: Standardization and Benchmarking

Today, LPS implementation is expanding globally, with documented use in 16 countries across all major continents. Glenn Ballard is currently leading an effort to create an LPS benchmark, aiming to standardize best practices, answer common questions, and provide organizations with a means to measure their implementation against an ideal state.

This initiative reflects a growing recognition of the need for consistent application and measurable results. The future of the LPS hinges on its ability to adapt to evolving industry needs while maintaining its core principles.

Conclusion

The Last Planner System’s journey from early experiments to global implementation demonstrates its enduring relevance. By combining practical insights with rigorous research, the LPS has proven its ability to improve construction project outcomes. Its continued evolution, driven by standardization efforts and integration with other methodologies, ensures its continued impact on the industry